Product Description:

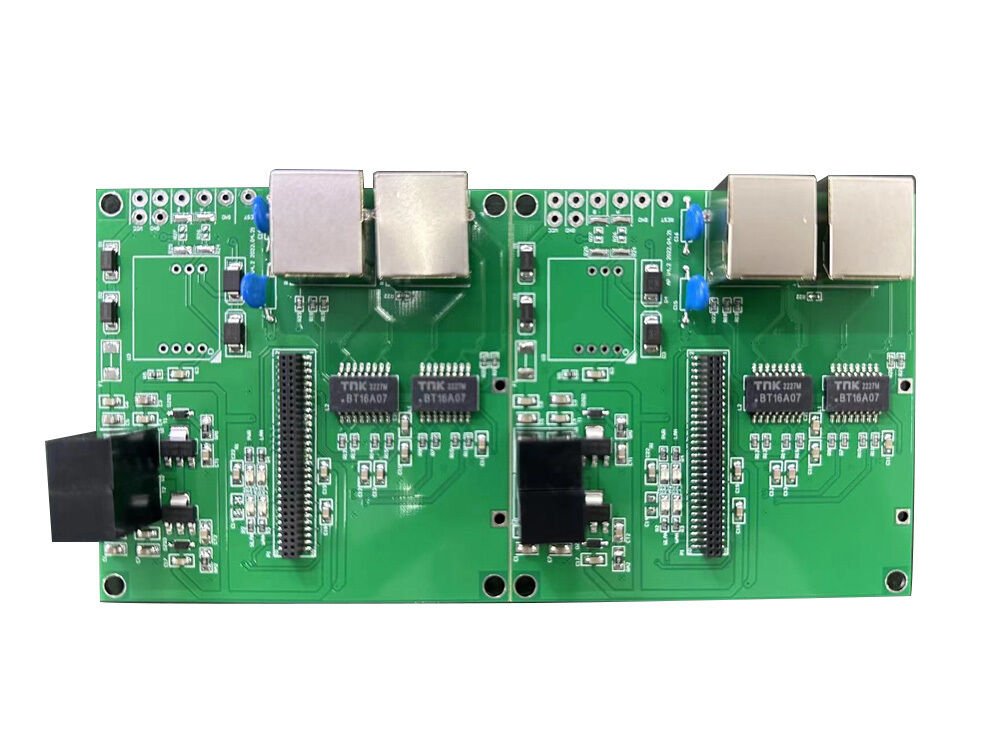

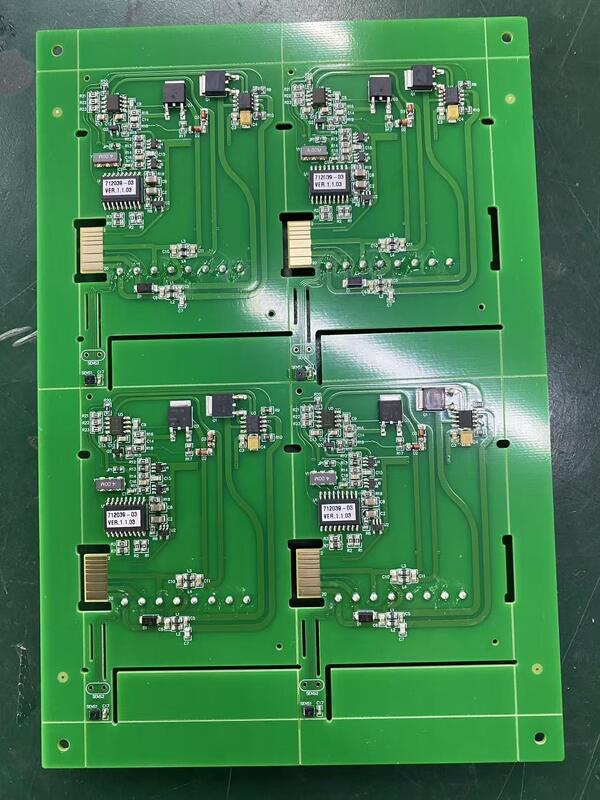

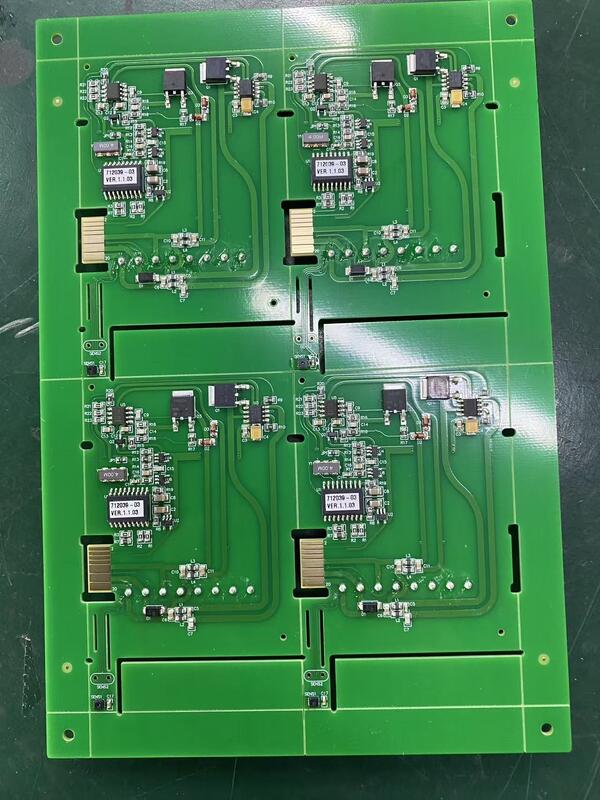

The Communication PCB Assembly is a highly advanced and reliable solution designed to meet the rigorous demands of modern communication systems. This product features a sophisticated 6-layer PCB configuration, which ensures excellent signal integrity, enhanced electrical performance, and superior mechanical strength. The multilayer design is essential for accommodating complex circuit layouts and high-density components, making it ideal for applications requiring robust communication capabilities.

At the core of this Communication PCB Assembly is the HDI (High-Density Interconnect) PCB board technology. HDI PCBs are renowned for their ability to support finer lines and spaces, smaller vias, and higher connection pad density, which are crucial for compact and high-performance communication devices. The use of HDI technology in this assembly allows for greater functionality in smaller form factors, enabling manufacturers to produce more efficient and compact communication equipment.

Impedance control is a critical feature of this Communication PCB Assembly, ensuring that signal transmission remains stable and distortion-free across the board. Controlled impedance is vital in high-frequency communication circuits because it minimizes signal reflections and crosstalk, thereby enhancing overall signal quality and reliability. This feature is especially important for applications involving high-speed data transmission and sensitive RF signals, where maintaining signal integrity is paramount.

The surface finishing options available for this product include ENIG (Electroless Nickel Immersion Gold) and HASL (Hot Air Solder Leveling) Lead Free. ENIG finishing provides a flat, solderable surface with excellent corrosion resistance and long shelf life, making it highly suitable for fine-pitch components and advanced assembly processes. On the other hand, HASL Lead Free finishing is an environmentally friendly option that ensures reliable solder joints and good wettability. These surface finishes guarantee that the Communication PCB Assembly meets stringent quality standards and is compatible with various assembly techniques.

Another notable attribute of this Communication PCB Assembly is the diverse via types incorporated into its design. The product features Through Hole, Blind, and Buried vias, which collectively enhance the electrical performance and routing flexibility of the PCB. Through Hole vias pass entirely through the board, Blind vias connect outer layers to one or more inner layers without going through the entire board, and Buried vias connect only inner layers. This variety in via types allows for optimized signal paths, reduced parasitic inductance, and increased component density, all of which contribute to superior communication performance.

This Communication PCB Assembly is manufactured by a reputable Manufacturer known for its commitment to quality, precision, and innovation. The Manufacturer employs state-of-the-art fabrication techniques and strict quality control measures to ensure that each PCB assembly meets the highest industry standards. One of the key features offered by this Manufacturer is the inclusion of thick copper layers within the PCB stack-up. Thick copper enhances the current-carrying capacity of the board, improves thermal management, and increases the overall durability of the assembly. This makes the Communication PCB Assembly particularly suitable for power-intensive communication devices and demanding operating environments.

In summary, the Communication PCB Assembly stands out as a top-tier product combining advanced HDI PCB technology, 6-layer construction, precise impedance control, versatile via types, and premium surface finishing options like ENIG and Lead Free HASL. With thick copper integration and expert craftsmanship from the Manufacturer, this assembly delivers exceptional electrical performance, mechanical robustness, and long-term reliability. It is an ideal choice for manufacturers and developers aiming to build cutting-edge communication equipment that requires superior PCB assemblies capable of handling complex signals and stringent environmental conditions.

Features:

- Product Name: Communication PCB Assembly

- Specification: PCB Customized Size

- Surface Finishing: ENIG, HASL Lead Free

- Impedance Control: Yes

- PCB Quality System: ROHS compliant

- Viatype: Through Hole, Blind, Buried

- Designed by a trusted Manufacturer specializing in high-quality PCB assemblies

- Enhanced surge protection features to ensure reliable communication performance

- Advanced surge protection mechanisms integrated for optimal circuit safety

Technical Parameters:

| Product Name |

Communication PCB Assembly |

| PCB Layers |

6 Layers |

| Application Field |

5G Communication, Communication Infrastructure |

| Impedance Control |

Yes |

| Specification |

PCB Customized Size |

| Solder Mask Color |

Blue, Green, etc. |

| PCB Board |

HDI PCB |

| Customized |

Yes |

| Communication PCB |

High Tg170 and High Tg180 |

| PCB Quality System |

ROHS |

| Special Features |

Thick Copper for Enhanced Communication Infrastructure |

Applications:

The Communication PCB Assembly, featuring 6 layers and advanced via types including Through Hole, Blind, and Buried vias, is an essential component in the rapidly evolving field of 5G communication. This product is meticulously designed and manufactured to meet the high-performance demands of modern communication systems, ensuring reliable signal transmission and enhanced connectivity. As a customized PCB solution, it offers flexibility in size and specifications, allowing manufacturers to tailor the board to specific device requirements and application scenarios.

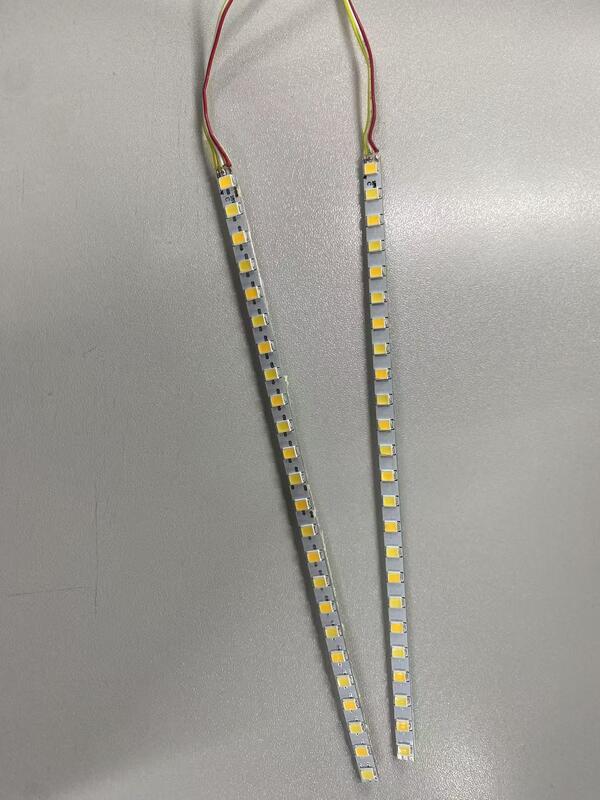

One of the primary application occasions for this Communication PCB Assembly is in 5G infrastructure equipment such as base stations, signal repeaters, and network routers. The thick copper layers incorporated into the design provide excellent current carrying capacity and thermal management, which are critical for handling the high-frequency signals and power levels typical in 5G communication hardware. This makes the product particularly suitable for outdoor and industrial environments where durability and consistent performance are paramount.

In addition, this PCB assembly is widely used in communication devices that demand compact yet highly efficient circuit boards. The 6-layer design, combined with the use of Blind and Buried vias, allows for higher circuit density and improved electromagnetic compatibility. This is crucial in mobile communication devices, IoT gateways, and wireless communication modules where space constraints and signal integrity are significant considerations. Manufacturers benefit from the customized size options, enabling them to integrate the PCB seamlessly into various device architectures.

Furthermore, the Communication PCB Assembly is employed in testing and measurement equipment within telecommunications labs. The precision manufacturing processes ensure consistent quality and performance, which are essential for accurate testing of 5G communication signals and devices. Manufacturers rely on these PCBs to prototype and develop new communication technologies, leveraging the customizable features and robust design to accelerate innovation cycles.

Overall, this product serves as a cornerstone in the 5G communication ecosystem, bridging the gap between advanced electronic design and practical application needs. Manufacturers value its thick copper layers and versatile via options for creating reliable, high-performance communication solutions tailored to diverse scenarios, from large-scale network infrastructure to compact, portable communication devices.

Customization:

Our Communication PCB Assembly product offers exceptional customization services tailored to meet your specific needs. Featuring high Tg170 and high Tg180 materials, these PCBs ensure superior thermal stability and reliability for demanding applications. We provide PCB customized size options to perfectly fit your design requirements, making it ideal for advanced 5G communication systems.

With precise impedance control, our PCBs guarantee optimal signal integrity and performance critical for high-frequency communication devices. The assembly supports thick copper layers, enhancing current carrying capacity and enabling heavy current applications without compromising durability. Our commitment to quality is demonstrated by adherence to the ROHS standard, ensuring environmentally friendly and safe products.

Choose our Communication PCB Assembly services for robust, high-performance PCBs that excel in 5G communication environments, offering thick copper construction and heavy current handling capabilities customized to your specifications.

Support and Services:

Our Communication PCB Assembly product is backed by comprehensive technical support and services to ensure optimal performance and reliability. We provide expert assistance throughout the entire lifecycle of the product, from design consultation and prototype development to production and post-sales support.

Our technical support team is available to help troubleshoot any issues, offer guidance on integration and compatibility, and provide detailed documentation and resources. We also offer customization services to meet specific application requirements and ensure seamless communication within your systems.

With a focus on quality assurance, our services include rigorous testing and inspection processes to guarantee the highest standards of performance and durability. We are committed to delivering timely solutions and continuous improvements to enhance your experience with our Communication PCB Assembly products.

Partner with us for reliable technical support and tailored services that empower your communication technology projects to succeed.

Packing and Shipping:

Our Communication PCB Assembly products are meticulously packaged to ensure maximum protection during transit. Each PCB assembly is securely placed in anti-static bags to prevent electrostatic discharge damage. These are then cushioned with foam or bubble wrap to absorb shocks and vibrations.

The packaged assemblies are placed in sturdy, double-walled corrugated boxes designed to withstand rough handling and environmental factors. For larger orders, custom pallets and crates are used to facilitate safe transportation.

We employ reliable shipping partners and provide tracking information to ensure timely and secure delivery. All shipments comply with international shipping standards and regulations to guarantee the integrity of the product upon arrival.

Por favor verifique seu email!

Por favor verifique seu email! Por favor verifique seu email!

Por favor verifique seu email!  Por favor verifique seu email!

Por favor verifique seu email! Por favor verifique seu email!

Por favor verifique seu email!