Product Description:

Power System Protection

Power system protection is a critical aspect of electrical engineering that ensures the safe and reliable operation of electrical power networks. It involves the use of various devices and schemes designed to detect faults and abnormal conditions within the power system.

The primary goal of power system protection is to isolate only the faulty section of the network while maintaining power supply continuity to unaffected areas. This selective isolation helps prevent extended outages and minimizes damage to electrical equipment.

Protection mechanisms include relays, circuit breakers, fuses, and other automated systems that work together to monitor the power system continuously. When a fault or abnormal condition is detected, these devices act rapidly to disconnect the compromised part and protect the rest of the system.

Advancements in digital technology have greatly enhanced power system protection. Modern protection schemes use intelligent electronic devices (IEDs) and communication networks to provide faster, more accurate, and more adaptable protection solutions.

Features:

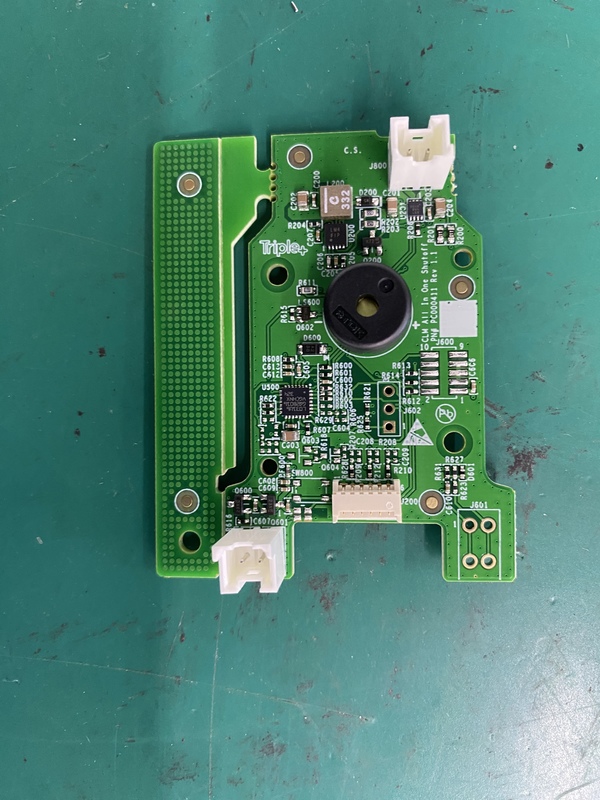

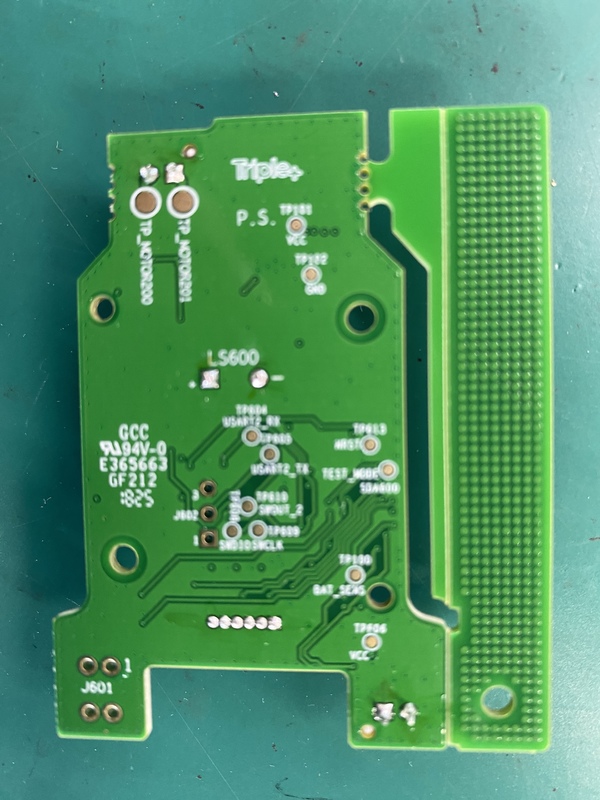

- Product Name: Power Protection PCB Assembly

- Certifications: UL, RoHS certified for reliable quality and compliance

- Silkscreen Color: White for clear and precise labeling

- RoHS Compliance: Available in both lead and lead-free options

- Customization: Fully customized to meet specific Power Safety PCB Assembly requirements

- Soldermask Colors: Available in Blue, Green, Black, Red, and Matt color finishes

- Designed to ensure optimal performance and safety in Power Safety PCB Assembly applications

- High-quality materials and manufacturing processes used in every Power Safety PCB Assembly

Technical Parameters:

| Product Name |

Electricity Guarding Printed Circuit Board Assembly / Current Protection Printed Circuit Board Assembly / Power Security PCB Assembly |

| Thickness |

1.6mm |

| Hole Minimum Diameter |

0.1mm |

| Solder Mask Color |

Green, Blue, Black, Red, White, Matt Color |

| Additional Soldermask Options |

Blue, Green, Black, Red, Matt Color |

| Maximum Size |

1200 x 400 mm |

| Guarantee |

1 Year |

| Certifications |

UL, RoHS |

| Product Compliance |

ROHS |

| Customized |

Yes |

Applications:

The industrial sector plays a critical role in driving economic growth and innovation. It encompasses a wide range of manufacturing and production activities that form the backbone of many economies worldwide.

Electric vehicles (EVs) represent a transformative shift in the automotive industry. With increasing focus on sustainability and reducing carbon emissions, EV cars are becoming more popular as an eco-friendly alternative to traditional gasoline-powered vehicles.

Communication technologies continue to evolve rapidly, shaping how people connect and share information. Advances in this field facilitate real-time interaction and enable seamless integration across various platforms and devices.

Capital construction involves the development of infrastructure and major projects essential for supporting economic activities. This includes the building of roads, bridges, commercial complexes, and other foundational structures that contribute to societal advancement.

Customization:

Our Power Protection PCB Assembly services offer highly customized solutions to meet your specific requirements. Manufactured in China or Cambodia, our Power Safety PCB Assembly products adhere to the highest quality standards, certified by ISO9001:2015, ISO13485:2016, IATF 16949:2016, and UL E476377, ensuring reliable and safe current protection printed circuit board assemblies.

We accommodate orders starting from a minimum quantity of just 1 piece, making our Power Security PCB Assembly ideal for both small-scale prototyping and large production runs. Pricing is available upon request to provide you with the best value tailored to your needs.

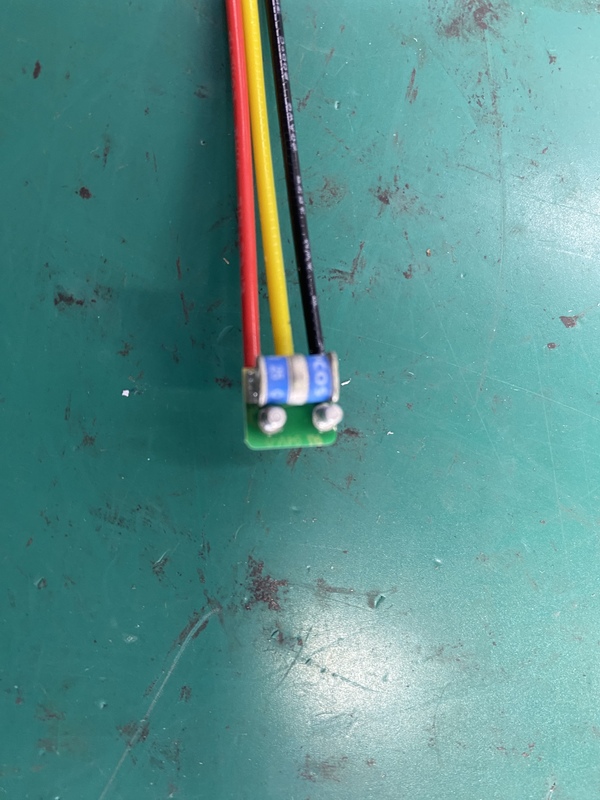

Each assembly features a standard thickness of 1.6mm and comes with a green solder mask color. We support both lead and lead-free RoHS compliance options to meet environmental and safety standards.

Packaging is carefully handled using ESD bags and shield bags to protect your Current Protection Printed Circuit Board Assembly during transit. Delivery time will be confirmed upon order placement, and payment terms are via TT for your convenience.

With our commitment to customization, we ensure that every Power Safety PCB Assembly is designed and manufactured to your exact specifications, backed by our comprehensive certifications and quality assurance processes.

Support and Services:

Our Power Protection PCB Assembly is designed to provide reliable and efficient power management for your electronic devices. To ensure optimal performance, it is essential to follow proper installation and maintenance guidelines.

Technical support for the Power Protection PCB Assembly includes assistance with installation, troubleshooting, and operational guidance. Our team is equipped to help diagnose issues related to power surges, component failures, and connectivity problems.

We recommend regular inspection and testing of the PCB assembly to prevent unexpected downtime. Use only compatible components and adhere to the specified voltage and current ratings to maintain safety and functionality.

For service and repair, authorized technicians should handle any disassembly or replacement procedures to avoid damaging the assembly. Firmware updates, if applicable, should be performed following the official instructions provided with the product.

Additional resources such as user manuals, datasheets, and installation guides are available to support your use of the Power Protection PCB Assembly. Please refer to these documents for detailed technical specifications and operational tips.

Packing and Shipping:

The Power Protection PCB Assembly is carefully packaged to ensure maximum protection during transit. Each unit is placed in an anti-static bag to prevent electrostatic discharge damage, followed by cushioning materials such as foam or bubble wrap to absorb shocks and vibrations.

The packaged assemblies are then securely placed in sturdy corrugated boxes, with additional padding to minimize movement inside the box. All packages are clearly labeled with handling instructions and product information to facilitate safe and efficient shipping.

We use reliable shipping carriers and offer various shipping options to meet your delivery needs. Tracking information is provided once the product has been dispatched, ensuring you can monitor your shipment until it arrives at your location.

For bulk orders, customized packaging solutions are available to further enhance protection and streamline handling. Please contact our customer service for special packaging requests or shipping inquiries.

FAQ:

Q1: Where is the Power Protection PCB Assembly manufactured?

A1: The Power Protection PCB Assembly is manufactured in China or Cambodia.

Q2: What certifications does the Power Protection PCB Assembly have?

A2: It is certified with ISO9001:2015, ISO13485:2016, IATF 16949:2016, and UL E476377.

Q3: What is the minimum order quantity for this product?

A3: The minimum order quantity is 1 piece.

Q4: How is the Power Protection PCB Assembly packaged?

A4: The product is packaged in an ESD bag and shield bag to ensure protection during shipping.

Q5: What are the payment terms for purchasing this product?

A5: The payment terms are TT (Telegraphic Transfer).

Q6: What is the delivery time for the Power Protection PCB Assembly?

A6: The delivery time is to be confirmed based on the order quantity and shipping location.

Q7: How is the price for the Power Protection PCB Assembly determined?

A7: The price is to be advised upon inquiry, depending on order quantity and specifications.

Por favor verifique seu email!

Por favor verifique seu email! Por favor verifique seu email!

Por favor verifique seu email!  Por favor verifique seu email!

Por favor verifique seu email! Por favor verifique seu email!

Por favor verifique seu email!