Suntek is a professional PCBA solution provider,specilizes in PCB production,components procurement,PCB assembly and a series service of wire harness and Box building.

We have high-qualified management team, experienced engineering,quality control&production team and skilled employees and possess advantaged supply chain,commitment to good quality,competitive price and on-time on delivery.

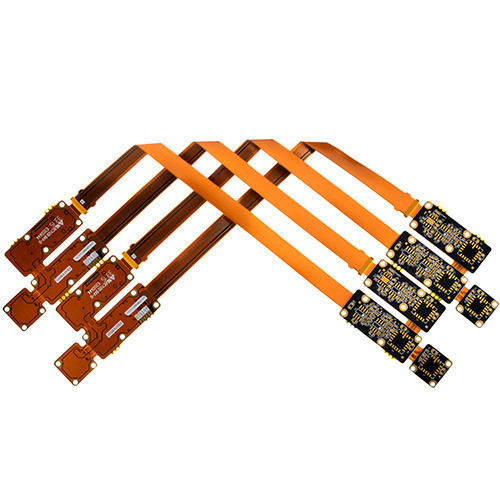

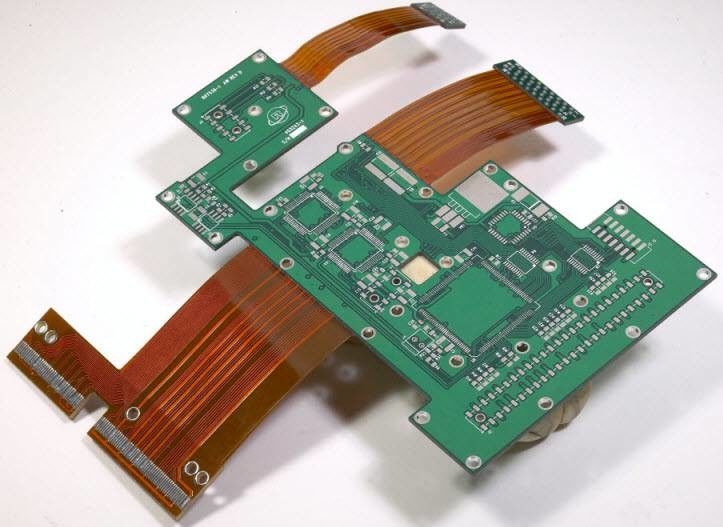

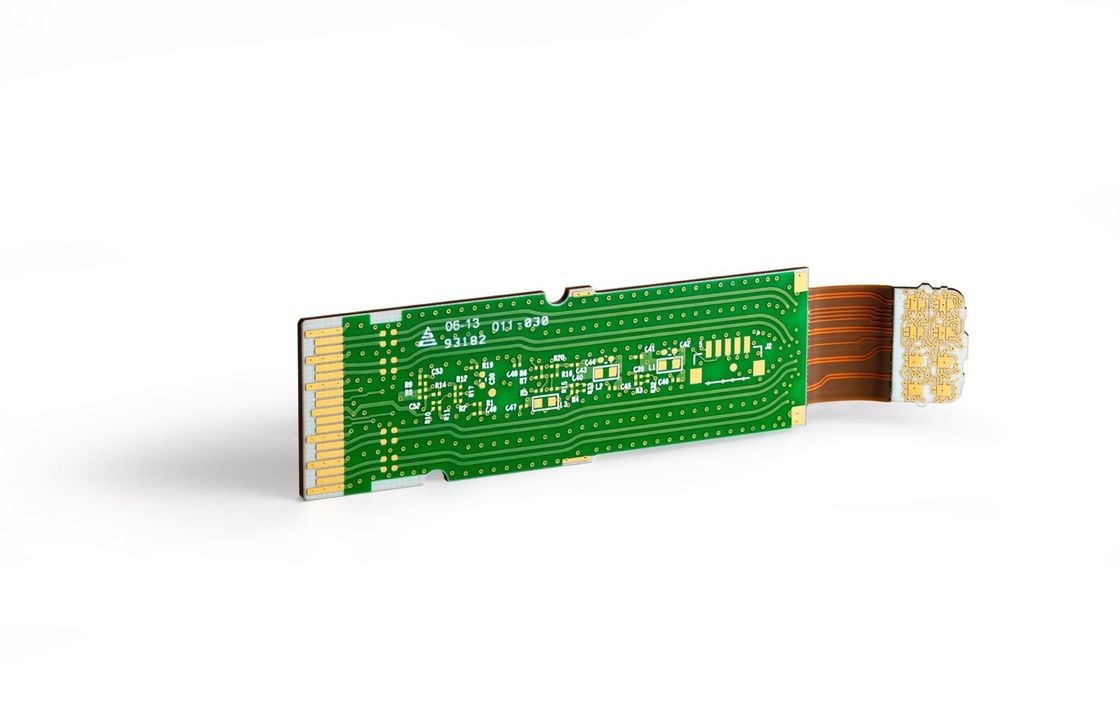

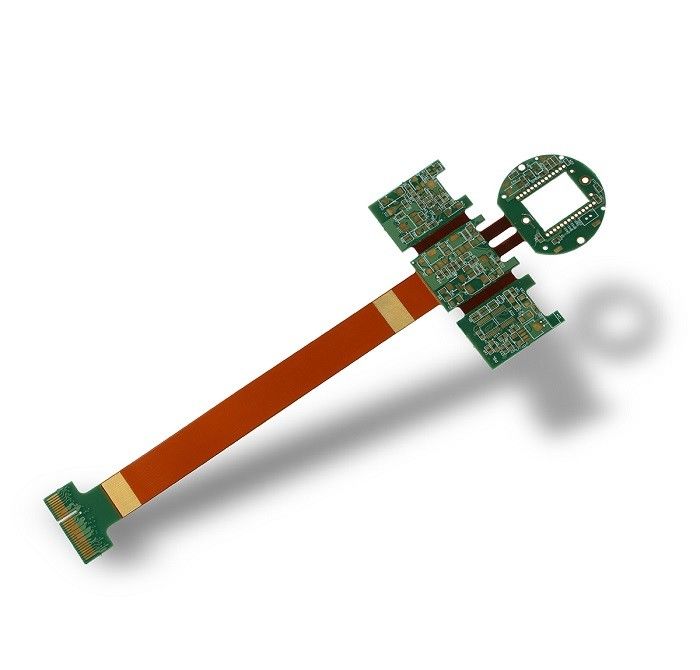

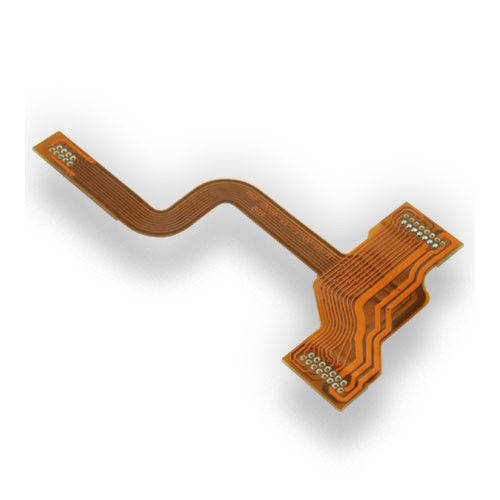

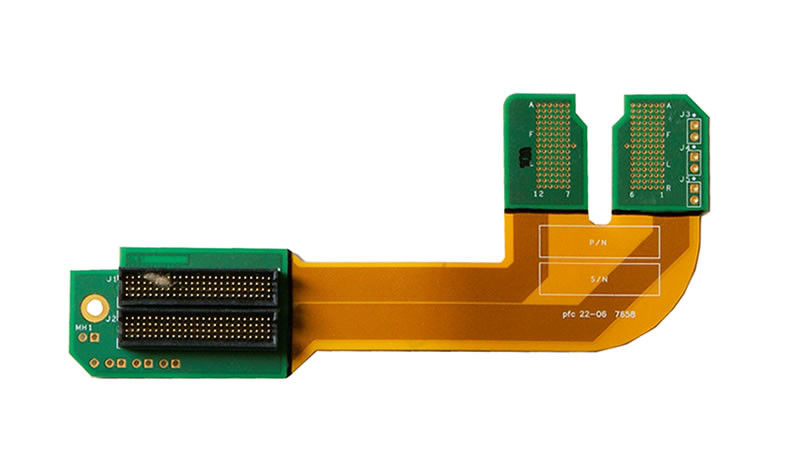

Rigid-flex

Rigid Flex PCB boards are composed of rigid and flexible printed circuit boards by vacuum lamination.

Flex-rigid PCBs are printed circuit boards highlighted by both rigid and flexible areas that make them ideally suited for a wide range of applications. The typical rigid-flex PCB circuit includes two or more conductive layers that comprise either flexible or rigid insulation material between each one - the outer layers may have either exposed pads or covers. Conductors are found on the rigid layers, while plated through-holes are found in both the rigid and flexible layers.

Assembly capabilities:

SMT Assembly, BGA Assembly, Through-Hole Assembly, Mixed Assembly, Rigid Flex PCB Assembly Services,

Electro Mechanical Assembly, Box Build Assembly, Product Assembly, Cable Assemblies.

Compliant with a wide range of standards including IPC 610 Class 2 and Class 3.

Our supports

We ensure cost transparency, BOM cost breakdown sharing

We have components suppliers from the Global.

We have a written process to advise customers of any schdule delays or product quality problems,by:

(1)Customer service procedure

(2)RMA procedure

(3)8D reports

(4)PDCA(Plan-Do-Check-Action) in customer service

We respond to the complaints,issues and queries in 24 hours, by:

(1) Weekly reports

(2) Customer supporting team to review communication times

(3) Customer satisfaction questionnaire

Aftersales services:

(1) 1-year guarantee period for all of products

(2) FOC repair

(3) Quick compensation parts to replace defectives.

|

Product Name

|

PCB Assembly

|

|

Plugging Vias Capability

|

0.2-0.8mm

|

|

Pcb Layers

|

2 Layers

|

|

Pcba Test

|

AOI, X-RAY, ICT and Function Test

|

|

Layers

|

2-10

|

|

Material Precision

|

0402+QFN+QFP

|

|

Pcb Quality System

|

ROHS

|

|

Pcb Assembly Method

|

BGA

|

|

Pcba Service

|

SMT+Function Test

|

|

Pcb Thickness

|

0.2-7.0mm

|

|

Min. Line Width/Spacing

|

0.1mm

|

|

Automotive Circuit Assembly Service

|

Providing high-quality PCB assembly solutions for motor vehicles

|

|

Motor Vehicle PCB Assembly Solutions

|

Expertise in assembling PCBs for various automotive electronic systems

|

|

Automobile Electronic Board Integration

|

Efficient integration of electronic boards in automobiles for optimal performance

|

Product Description:

Product Overview: Medical PCB Assembly

The Medical PCB Assembly is a high-quality and efficient solution for healthcare device electronics assembly. It is designed to meet the strict requirements of medical device electronic manufacturing, ensuring reliability and precision in medical system PCB integration.

Applications:

Medical PCB Assembly – Revolutionizing Healthcare Devices

Medical PCB Assembly is a highly advanced and specialized service that offers integrated solutions for medical system PCB integration and healthcare device electronics assembly. With the use of high-quality FR-4 material, this product ensures reliable and efficient PCB assembly for various medical devices. The silkscreen color options of white, black, and yellow further enhance its visual appeal and utility.

Application Field: Office

In today’s fast-paced world, medical offices require advanced and efficient equipment to cater to the needs of their patients. Medical PCB Assembly plays a crucial role in the smooth functioning of medical offices by providing reliable and accurate results. This product is commonly used in office equipment such as blood pressure monitors, pulse oximeters, and ECG machines, ensuring accurate readings and timely diagnosis.

Application Field: Test

Accurate and precise testing is essential in the medical field to diagnose and treat various ailments. Medical PCB Assembly is widely used in medical testing equipment such as ultrasound machines, MRI scanners, and X-ray machines. Its compact size and high-quality FR-4 material make it ideal for use in a variety of testing environments, providing reliable and accurate results for medical professionals.

Application Field: Medical Devices

Medical devices are constantly evolving to meet the growing demands of the healthcare industry. With the use of Medical PCB Assembly, manufacturers can design and assemble advanced medical devices such as pacemakers, insulin pumps, and defibrillators. The compact dimensions of 76*31*4.5mm (L*W*H) make it suitable for use in a wide range of medical devices, ensuring optimal performance and accuracy.

In conclusion, Medical PCB Assembly is a highly advanced and specialized product that is revolutionizing the healthcare industry. Its use in medical offices, testing facilities, and medical devices ensures reliable and accurate results, making it an essential component in the field of medicine.

Packing and Shipping:

Medical PCB Assembly - Packaging and Shipping

Our Medical PCB Assembly products are carefully packaged and shipped to ensure their safe delivery to our customers. We understand the importance of maintaining the quality and integrity of our products, especially in the medical industry. That's why we follow strict packaging and shipping guidelines to ensure that our products arrive at their destination in perfect condition.

Packaging

Each Medical PCB Assembly is first wrapped in anti-static bubble wrap to protect it from any physical damage during transportation. It is then placed in a sturdy, custom-made cardboard box with appropriate labeling and markings to indicate its fragility and handling instructions.

In addition, we use specialized foam inserts to secure the PCB assembly in place and prevent any movement or shifting within the box. This ensures that the delicate electronic components are well-protected and do not get damaged during transit.

Shipping

We work with trusted shipping partners to deliver our Medical PCB Assembly products to our customers. Our shipping partners are experienced in handling delicate and sensitive electronic equipment, and they follow proper handling and transportation procedures to ensure the safety of our products.

We also provide insurance for our shipments, so in the unlikely event of any damage during transit, our customers are fully covered.

Customized Packaging

At the request of our customers, we offer customized packaging solutions for our Medical PCB Assembly products. This can include additional packaging materials to provide extra protection or specific labeling and markings for easier handling and identification.

We understand that every customer has unique requirements, and we are happy to work with them to provide customized packaging solutions that meet their needs.

With our meticulous packaging and shipping processes, you can be assured that your Medical PCB Assembly products will arrive at their destination safely and in pristine condition. Contact us today to learn more about our packaging and shipping options for our Medical PCB Assembly products.

Por favor verifique seu email!

Por favor verifique seu email! Por favor verifique seu email!

Por favor verifique seu email!  Por favor verifique seu email!

Por favor verifique seu email! Por favor verifique seu email!

Por favor verifique seu email!